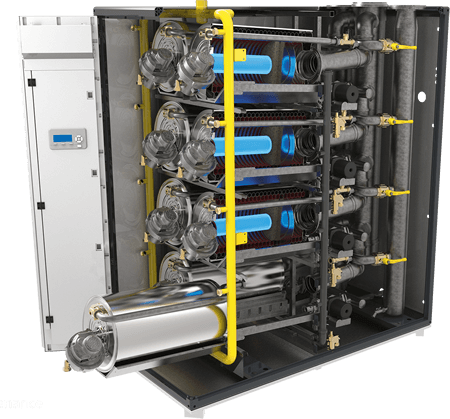

The Riello Array is a pre-packaged boiler plant, the new standard in boiler efficiency, redundancy and reliability.

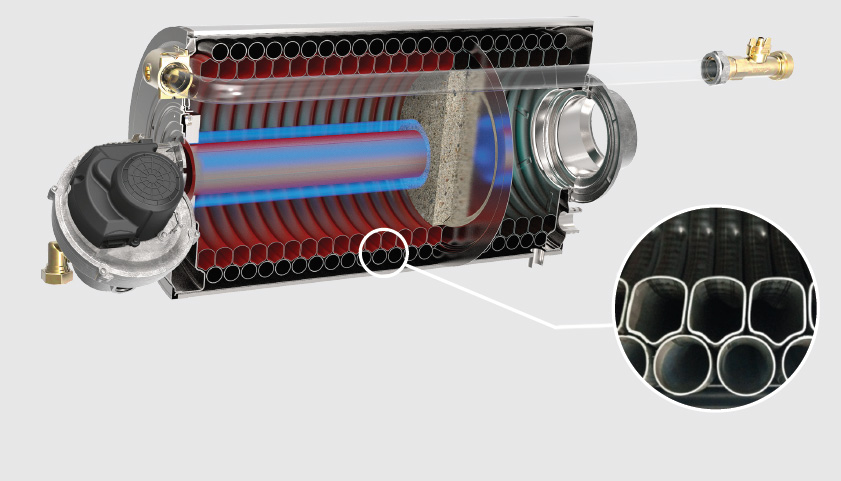

Each Array boiler utilizes multiple heat exchanger modules, providing high turndown and multiple boiler redundancy in one packaged unit.

A single Array boiler provides superior uptime reliability that is only found in larger boiler plants and multi boiler systems.

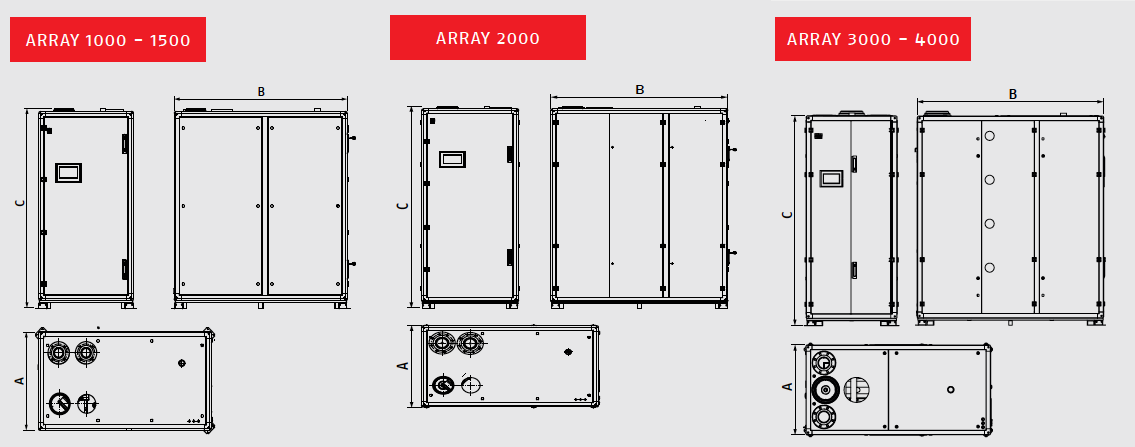

| Description | AR 1000 | AR 1500 | AR 2000 | AR 3000 | AR 4000 | |

| A - Width | inch | 33.3 | 33.3 | 33.3 | 35.4 | 35.4 |

| mm | 846 | 846 | 846 | 899 | 899 | |

| B - Length | inch | 60.8 | 60.8 | 60.8 | 72.8 | 72.8 |

| mm | 1544 | 1544 | 1544 | 1849 | 1849 | |

| C - Height | inch | 67.2 | 67.2 | 83 | 83 | 83 |

| (*) | mm | 1707 | 1707 | 2108 | 2108 | 2108 |

| Model | Unit | AR 1000 | AR 1500 | AR 2000 | AR 3000 | AR 4000 |

| Boiler Category | ASME Sect.IV | |||||

| Type of Gas | Natural Gas, Propane | |||||

| Max input rate | BTU/hr | 1,000,000 | 1,500,000 | 2,000,000 | 3,000,000 | 4,000,000 |

| (kW) | (293) | (440) | (586) | (879) | (1172) | |

| Min input rate | BTU/hr | 100,000 | 100,000 | 100,000 | 100,000 | 100,000 |

| (kW) | (29) | (29) | (29) | (29) | (29) | |

| Turndown | Rate | 10:01 | 15:01 | 20:01 | 30:01:00 | 40:01:00 |

| Gas Connections (NPT) | Ø Inch | 1 1/2" | 1 1/2" | 1 1/2" | 2" | 2" |

| Max. NG Pressure | Inch W.C. | 20 | 20 | 20 | 20 | 20 |

| (mbar) | (50) | (50) | (50) | (50) | (50) | |

| Min. NG Pressure | Inch W.C. | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| (mbar) | (10.0) | (10.0) | (10.0) | (10.0) | (10.0) | |

| Max. LPG Pressure | Inch W.C. | 20 | 20 | 20 | 20 | 20 |

| (mbar) | (50) | (50) | (50) | (50) | (50) | |

| Min. LPG Pressure | Inch W.C. | 8 | 8 | 8 | 8 | 8 |

| (mbar) | (19.9) | (19.9) | (19.9) | (19.9) | (19.9) | |

| Water Connections | Ø Inch | 3" | 3" | 4" | 4" | 4" |

| Max. Allowable Working Pressure (MAWP) | PSI (bar) | 80 (5.5) | 80 (5.5) | 80 (5.5) | 80 (5.5) | 80 (5.5) |

| Water Volume | Gallon (liter) | 12 (46) | 18 (69) | 24 (92) | 36 (138) | 48 (184) |

| Vent (slip-on) / Air Inlet Connections | Ø Inch | 6"/6" | 8"/8" | [8" or 10"]/10" (*) | ||

| (Ø mm) | (150/150) | (200/200) | ([200 or 250]/250) | |||

| Venting Materials | CPVC, PPs, Stainless Steel AL29-4C | |||||

| Max operating temperature | °F (°C) | 194 (90) | 194 (90) | 194 (90) | 194 (90) | 194 (90) |

| Max HE allowable temperature | °F (°C) | 210 (98.9) | 210 (98.9) | 210 (98.9) | 210 (98.9) | 210 (98.9) |

| Storage temperature | °F | 5 to 158 | 5 to 158 | 5 to 158 | 5 to 158 | 5 to 158 |

| (°C) | (-15 to 70) | (-15 to 70) | (-15 to 70) | (-15 to 70) | (-15 to 70) | |

| Ambient Room Temperature Operating Range | °F | 32 to 120 | 32 to 120 | 32 to 120 | 32 to 120 | 32 to 120 |

| (°C) | (0 to 49) | (0 to 49) | (0 to 49) | (0 to 49) | (0 to 49) | |

| Total Heating Surface Area | SQFT (m2) | 86 (8) | 129 (12) | 172 (16) | 258 (24) | 344 (32) |

| Standard Listings & Approvals | ETL, ASME, AHRI, CSD-1 and SCAQMD | |||||

| Electrical Requirement | V/Ph/Hz | 120/1/60 | 120/1/60 | 230/1/60 | 230/3/60 | 230/3/60 |

| FLA (**) | 20.3 | 24.0 | 20.1 | 20.1 | 30.2 | |

| Weight (Dry) | lbs (kg) | 1058 (480) | 1323 (600) | 1676 (760) | 2315 (1050) | 2998 (1360) |

| Dimensions WxHxD (***) | Inch | 33.3x67.2x60.8 | 33.3x67.2x60.8 | 33.3x83x60.8 | 35.4x83x72.8 | 35.4x83x72.8 |

| (mm) | 846x1707x1544 | 846x1707x1544 | 846x1707x1544 | 899x2108x1849 | 899x2108x1849 | |

TEN YEAR HEAT EXCHANGER WARRANTY

Riello warrants that the heat exchanger of the Boiler shall be free of defects in material and workmanship for TEN (10) YEARS from the date of manufacture.

Riello warrants that the Boiler and approved accessories designated by Riello as standard equipment shall be free of defects in manufacture, material and workmanship for 18 months from shipment or 12 months from start-up (whichever comes first).