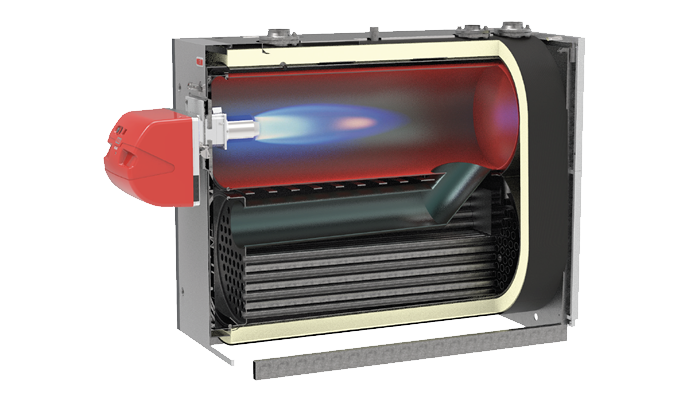

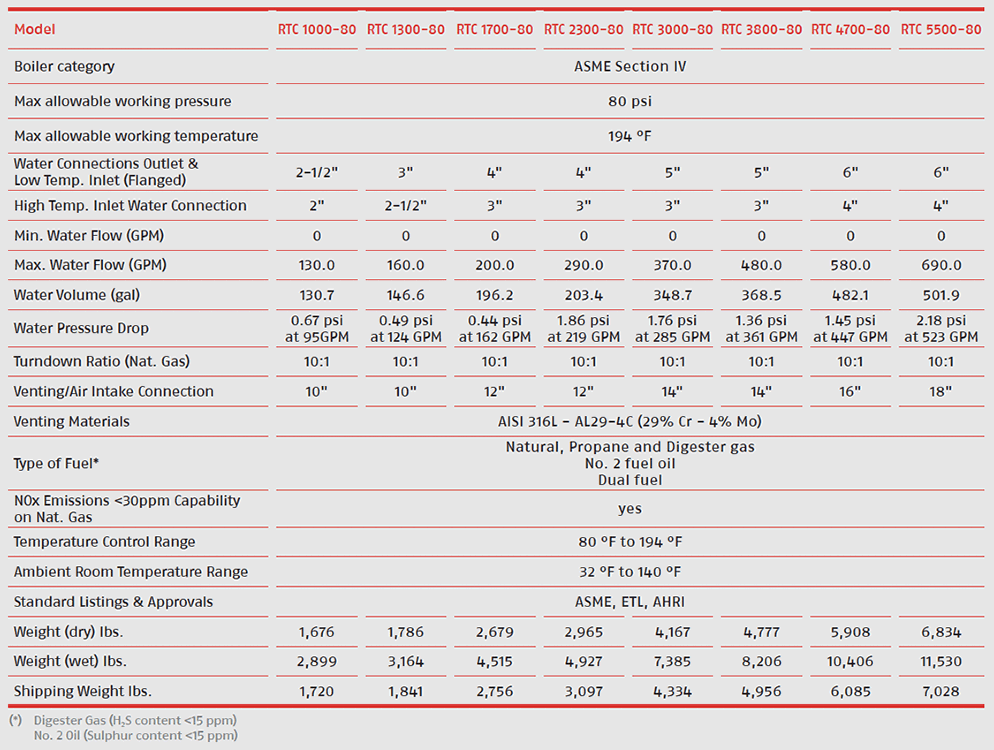

Riello high-efficiency condensing boilers are designed both for retrofit and new construction projects. Project costs are reduced thanks to the high water content heat exchanger, which doesn't require a minimum flow rate and eliminates the need of an expensive dedicated boiler circulator. Best quality materials used for all components ensure high reliability and longer service life.

Condensing boiler technology is the most efficient and ecological form of fuel heating available today. In particular, this technology recovers the latent heat retained in flue gas condensation. This latent energy is normally discharged to the chimney and is wasted in other heating systems. Thanks to the lower fuel consumption combined with the lower heating costs, condensing boilers usually pay for themselves in few years, reducing costs up to 20% in comparison with conventional heating. Furthermore, a modern condensing heating system increases the value of the building as well as quality of life by reducing emissions. High efficiency condensing equipment achieves qualifying points for LEED certification of commercial buildings.

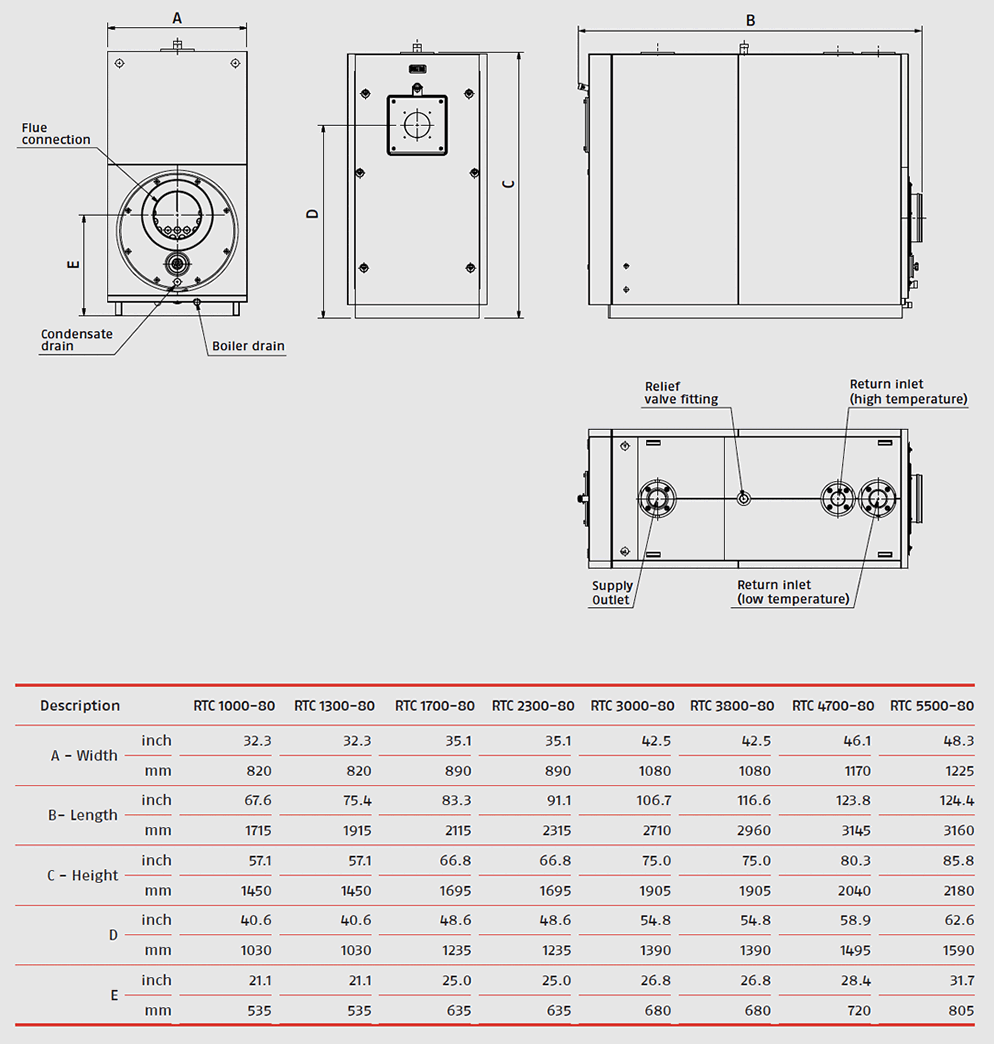

Large heat-transfer surfaces, a counter-flow heat exchanger design and dual inlets for different return water temperatures together optimize condensation opportunities.

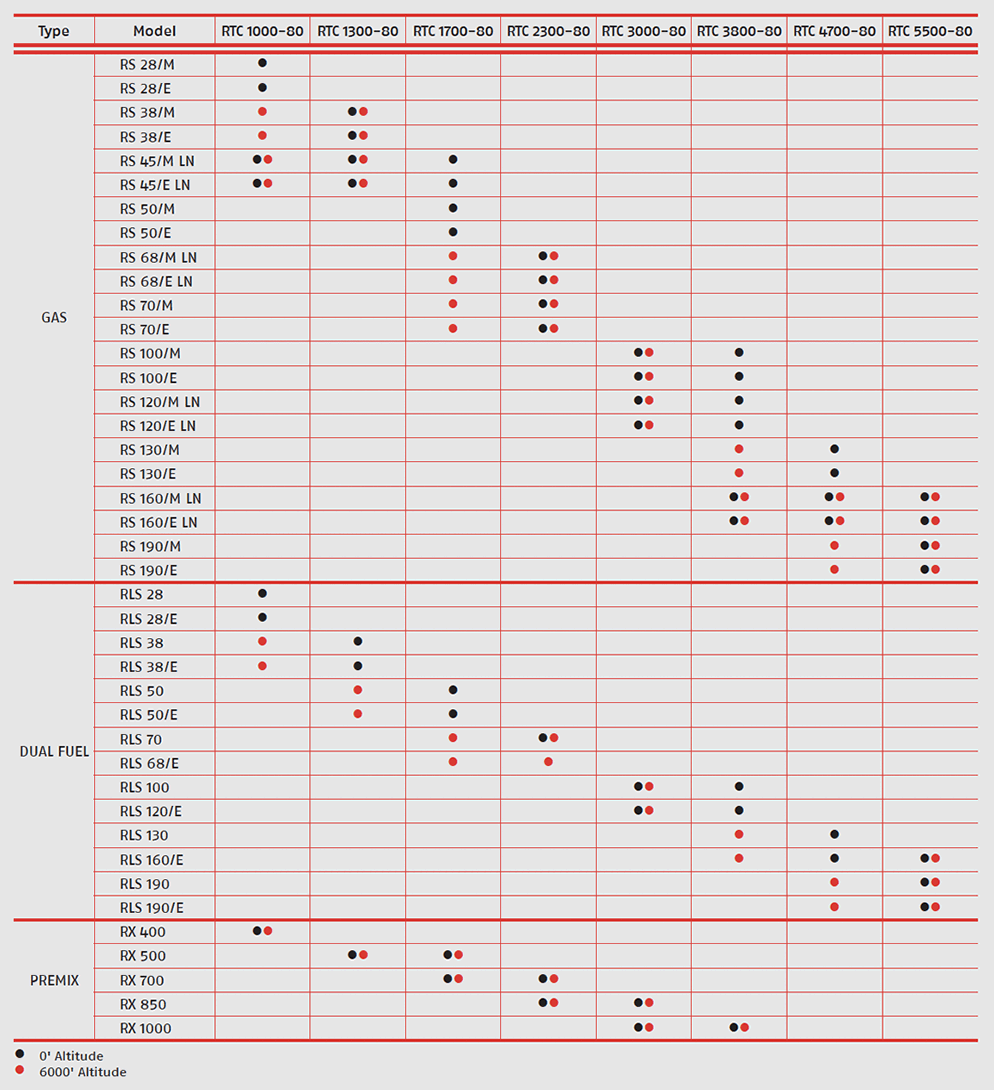

The RTC condensing boiler series could be equipped with two-stage, fully modulating or premix forced-draft burners that achieve extremely low pollutant emissions meeting the most stringent NOx and CO requirements.