HISTORY

Our History

Decade '2020

2022

Riello celebrates 100 years since its foundation and continues to innovate with smart and sustainable solutions.

2021

Riello launches a new line of residential boilers designed to be 20% hydrogen powered and to be integrated with IoT systems for remote control of comfort and consumption.

Riello has also launched an ambitious project to develop a range of burners and blown boilers (condensing boilers combined with burners), specifically developed to operate efficiently and safely with green hydrogen.

It has completed tests at the Combustion Research Centre in Angiari (Verona) on a series of condensing blown boiler units fuelled 100% by hydrogen, achieving excellent performance in terms of eliminating carbon oxides in the flue gas (CO-CO2) and very high energy efficiency.

2020

Riello becomes part of Carrier Global Corporation, which becomes an independent, listed company following its successful spin-off from United Technologies.

With the TAU N range, Riello is one of the few companies on the market that can boast high water content condensing boilers up to 3 MW. The 3-pass stainless steel flue gas exchanger, produced in the centre of excellence in Volpago del Montello, is the heart of the technology that guarantees highly efficient combustion and low emissions. The range is offered in combination with an RX series pre-mixed gas burner produced and developed in the Legnago factory.

TAU N

Represents one of the highest expressions of Riello's great expertise in the commercial segment.

Ultra Low NOx technology

The combustion gas recirculation (FGR) technology is based on the partial recirculation of combustion fumes inside the burner and allows very low values of polluting emissions to be obtained. Riello is the world leader in Ultra Low NOx burners with FGR technology from 195kW to 19.5MW.

Decade '2010

2019

Riello expands its product portfolio with the introduction of Domus ES, the new split heat pump with indoor basement unit. A heat pump that meets all the heating, air conditioning and domestic hot water needs of a housing solution in a residential environment by exploiting the potential of renewable energy. In April 2019 the Riello Array boiler wins the Industry Awards at the MCEE fair in Montreal, Québec, Canada2018

Launch of the Residence and Family boilers, top of the range of the Riello stable: products that continue the renewal process of Riello wall platforms. An innovative way of conceiving the products offered to the market, which is based on 2 design guidelines: profound technological innovation to ensure maximum rationalization of consumption and primary attention to design to allow easy insertion into domestic environments and easier brand recognition. Riello decides to be even closer to the supply chain of professionals who daily choose it for their daily work with Riello in Movimento (RiM): a road show that has entered the heart of more than 270 Italian cities with information and continuous training meetings with over 9,000 Professionals met.2016

Riello becomes part of UTC Climate, Controls & Security, a leading provider of heating, ventilating, air conditioning (HVAC), a unit of United Technologies Corporation.2015

Riello reaches the primacy in Europe on monoblock premix burners at very low NOx emissions, reaching the maximum power of 1850 kW and 9 ppm NOx, with the RX 1800 SP/V model.Riello joins EXPO 2015 and brings its presence at Museum of Science and technology "Leonardo Da Vinci" with briket, a burner manufactured in 1950 which converted the traditional wood stoves.

2014

Riello extends its product range of boilers for professional modular launching the new engine condensing 150KW Helix at peak performance

2013

Market launch of Hybrid, the first hybrid system built for residential applications.2012

Beginning of production of boilers on the Chinese market

Decade '2000

The industrial structure of the Group is consolidated while new entrants to export markets.

In September Riello Trade Division was created with the task of supervising the sale of the entire catalog Riello that offers solutions and services that give customers complete satisfaction.

2008

It has been started the conversion of the plant in Piombino Dese (Padua) for the production of solar panels and boilers that marks the entrance of Riello in the world of renewable energy. In 2009 begins the start up of the production site in China.

2005

Over 500,000 burners manufactured and sold in only one year.

2002

The work to expand the Center of Excellence is completed.

2001

Decade '90

A new Division is born to oversee autonomy in the sale of the entire catalog. Renewed effort in communication as it was in the past, with the aim of making the public aware of the new committment and organization of the Italian brand Riello: a Riello that offers solutions and services to grant to the customers complete satisfaction.

A new plant for the production of boilers was built in 1993 in record time, and in 1997 starts the production of burners in a new modern factory in Legnago.

1998

Focus on the core business: The Riello Burners brand is born.

1997

The new Center of Excellence for Product development and burner production is inaugurated in Legnago.

1996

Riello opens a Representative Office in Beijing.

1992

The Combustion Research Center doubles in size.

The Gulliver Blu Low Nox burner is launched.

Decade '80

1985-90

These were years of great expansion in foreign markets, with the creation of foreign subsidiaries in major European countries: England, Germany, France, Belgium, Switzerland. In Italy there has been a radical change in the sales with the merger of the sales networks and Isotherm Riello (1987) and the creation of a new brand that consisted of a red triangle and four circles to symbolize the expansion of the company into new markets. Expansion in communications by sponsor the Benetton Formula 1 car for five years. Meanwhile, a complete Riello catalog with products for heating and cooling systems is started to be commercialized. Since 1986, within few years, the company lauches on the market, in addition to historical burners, about 140 product families.

1983

The Center of Excellence on Combustion was opened in Angiari (Verona) to develop and test burners.

1980

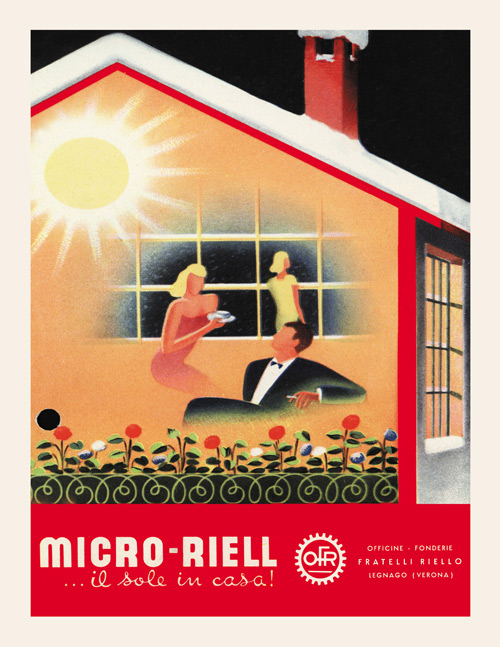

It Is established a new holding company of the group called "OFR Officine Fratelli Riello SpA ", while the Company changed its name "RBL Riello Burners Legnago SpA" The financial O.F.R. includes all of the 10 group companies operating in Italy and abroad. The strong development of industrial activities of Riello, with new investments on products and sales organizations in Italy and abroad, will extend throughout the decade. In the meantime, Riello built a new plant in Mississauga, Canada to serve the North American Country.

Decade '70

1979

Mectron is manufactured: the electronic burners of the 80's.

1976

Burners are sold for the first time on the USA market.

1973

The Company becomes a join stock named "O.F.R. Officine Fratelli Riello".

1971

Increase of sales in European and Extra Europe markets.

Decade '60

1962

Riello Export is established in Padua (Italy) with the aim of coordinating and developing all acrivities of the foreign companies.

1960

The 60’s open an important period of development either for the Company and for the general Italian society. These are the years where the TV commercials expanded and Riello launch a very popular and successful pubblicity on TV “Unca Dunca” to develop Riello brand.

With some important commercial strategies a strong Italian Distribution Network is established.

Decade '50

1958

The Special Tool Machines department is set up for the automation of the main components for the burners.

1955

Together with the burners production in these years Riello introduces other products such as air conditioning appliances. At first these new product line is imported from USA, then they started to be manufactures inside Riello’s factory.

1950

Production Facilities expanded to meet the demand for burners in thermal application.

Decade '30 - '40

1945

Production gradually resumes its activity after the interruption caused by the Second World War and it is again directed towards heavy oil burners, especially considering the success of this fuel on the domestic market for residential and industrial heating applications.

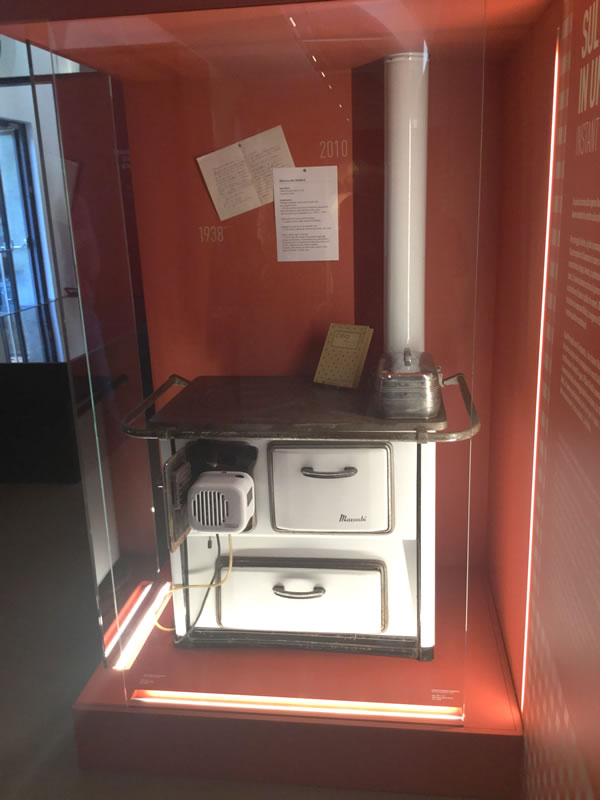

1938

Due to the crisis of heating sector, the Company addresses its production to Special Tool Machines for the domestic market.

1936

Due to a strong reduction in the availability of liquid fuels, new automatic special burners for use with coal are developed and produced.

Decade '20

1929

The first factory is built, the following years will see a steady development of the production due to the specific requirements of the domestic market.1925

The gasoil crisis sets the problem of adapting burners to the new heavy oil fuel. In terms of production this is an important innovation which involves much more complex research & development.1923

The idea of adapting the domestic oil burners, for long time already used in the U.S., becomes the main purpose of Riello; the first light oil burner is produced to be used in bakers’ ovens and for special applications.1922

The company was founded after the end of the First World War by the owners as direct workers in a first craft workshop.