NEWS

DR SE FGR SERIES

Industrial Dual Block Gas Burners FGR Ready

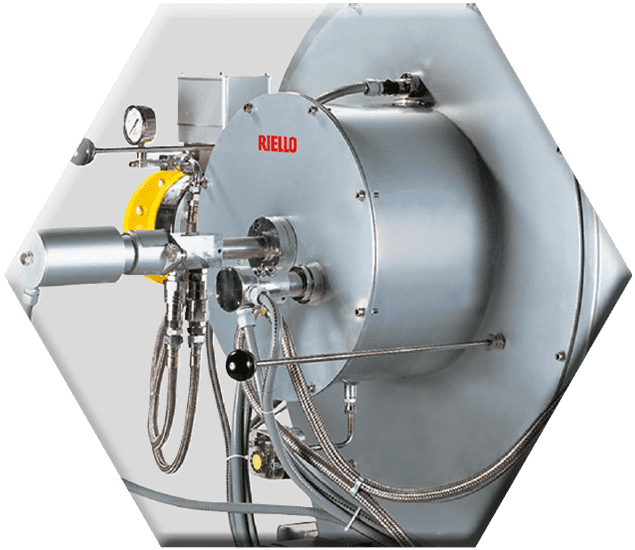

The new DR SE FGR burner platform represents the evolution in Riello Burners industrial product range for high power applications.

They are dual block burners for applications in in big civil heating plants (i.e. hospitals, district heating) and industrial processes (i.e. food chemicals, textile industry) with a remarkable thermal demand. They can be matched with hot water boilers, steam and thermal oil generators.

These burners allow to realise a modular and flexible combustion system adding a preparation fuel unit, a gas train, a control panel and a fan. Control panel with high-end control box can be supplied installed on burner board.

These burners are supplied with electronic air-fuel ratio control in order to obtain a perfect output control and to assure a correct low polluting combustion and a safe operation on all modulation range.

Preheated air can also be used as in the oil diathermic generators and other heat recovery systems.

The modulating regulation always allows to reach a wide modulation ratio and optimal fluid-dynamics conditions for a good combustion.

The low-NOx combustion head allows to reach, on natural gas operations, NOx emissions ≤ 80 mg/kWh without FGR use (≤ 50 mg/kWh with 10% FGR).

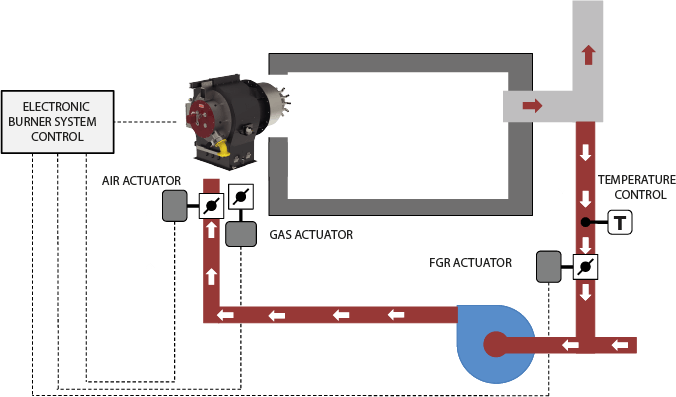

FGR TECHNOLOGY

Due to the significant increase of pollutants in these last years, attention to performance, energy efficiency and emission reduction is becoming more important all around the world.

In order to comply the increasing demand of very low NOx emissions, RIELLO has developed a new range of Dual Block burners equipped with advanced Low NOx combustion heads and compatible, if needed, with the FGR (Flue gas Recirculation) low emission technology, in order to comply with the most restrictive emission limits.

FGR technology is based on the recirculation of a part of the exhaust gas, which are mixed with air upstream of the burner; the Digital Burner Management System, through the action of independent servomotors, allows the control of air, fuel and exhaust gas proportion in every working point, in order to reach very low NOx emissions, while maintaining high reliability and safety of operation.

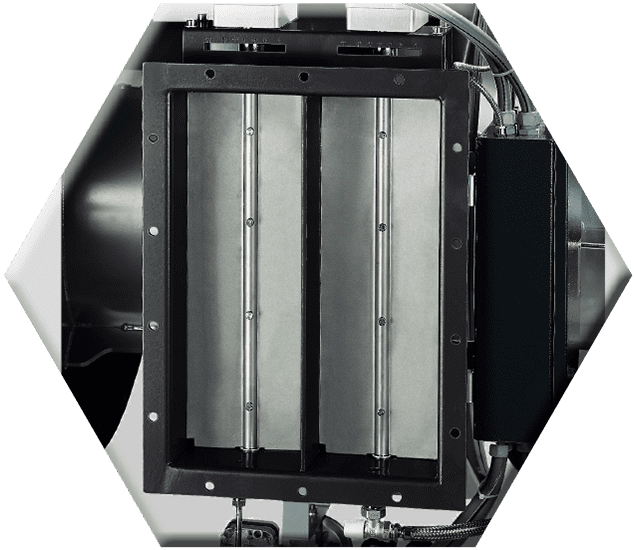

AIR SUCTION CIRCUIT

The air suction circuit of DR SE FGR burners is designed with two independent air ducts, each of them equipped with an independent high precision servomotor to control the air flow.

This particular design allows to obtain primary and secondary air flows to the combustion head in order to obtain staging combustion system (see “Combustion head” section).

Example of axial swirl register device (on demand)

Example of air dampers

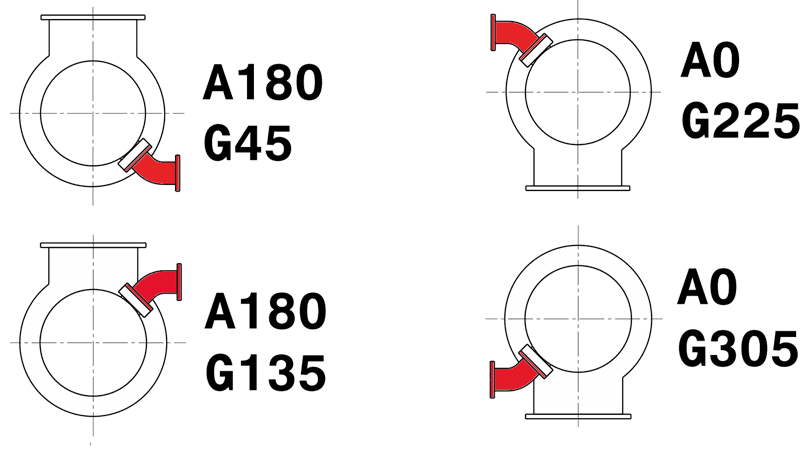

BURNER LAYOUT - ELBOW

Highly customizable layout.

Burner layout can be easily adapted according to plant requirements, orientating air flange from bottom or from the top and with 8 different possibility of gas flange orientation (final elbow design can be modified according to the desired orientation).

Final gas elbow orientation to be defined before order.

15/09/2022