NEWS

Steel Pro Power

Floor-standing gas condensing units for indoor use

STEEL PRO POWER is the new modular floor-standing gas condensing system, conceived and developed with the aim of maximizing flexibility and simplicity of installation, guaranteeing the continuity of service typical of modular systems.

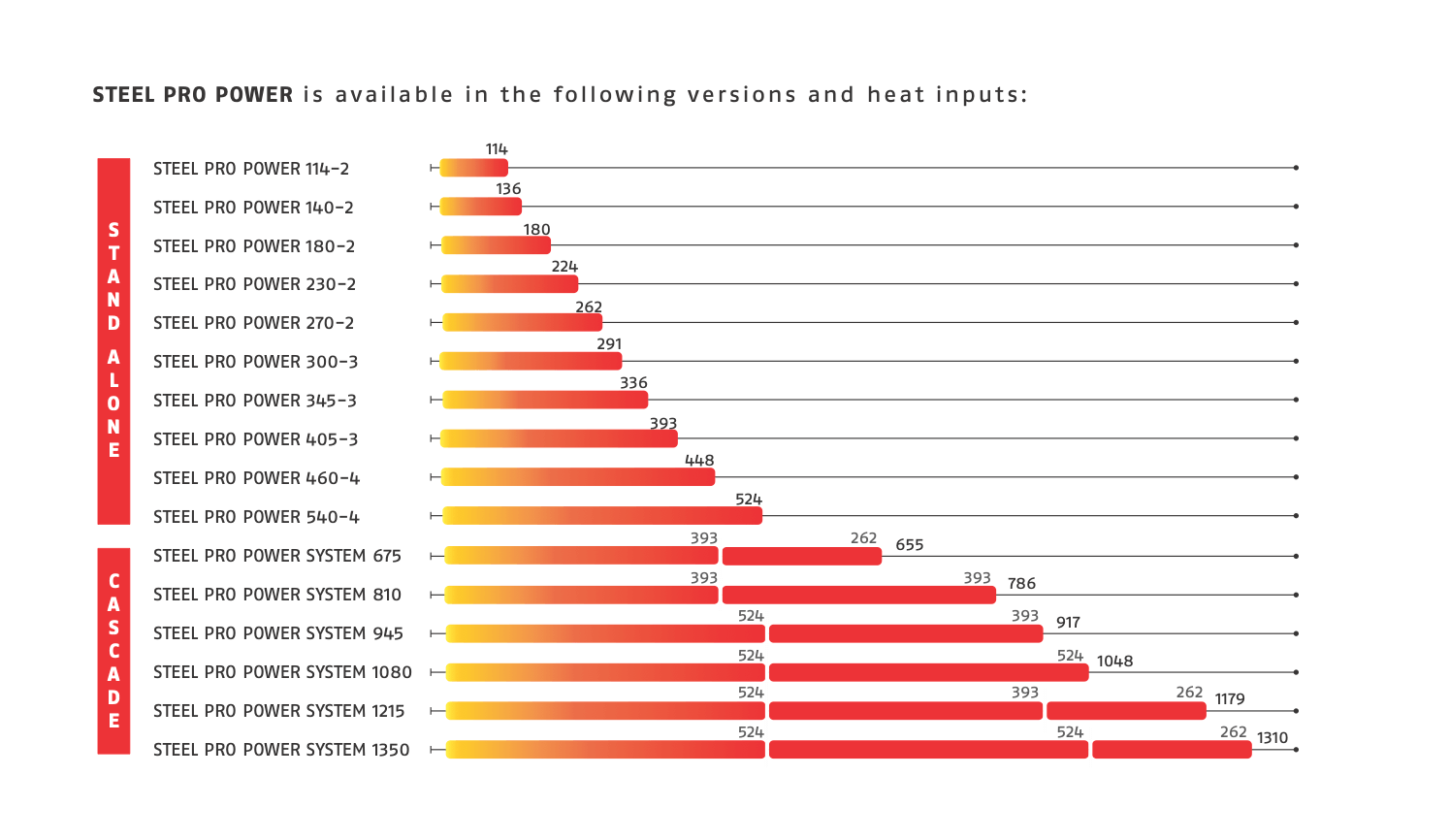

With STEEL PRO POWER a wide range of products is offered, as this can be installed either in single configuration (from 114 up to 540 kW) or in cascade (from 655 up to 1310 kW) with the use of specific accessories.

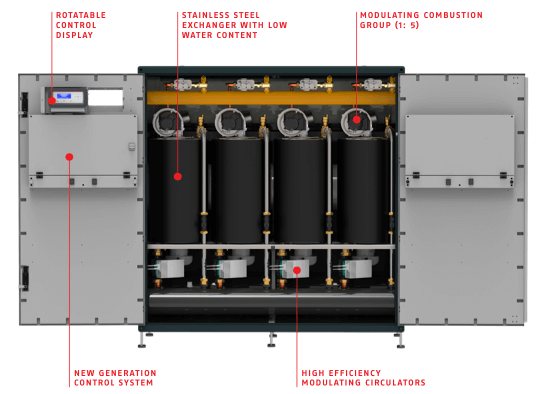

The cabinets, consisting of a frame assembled in anodised aluminum and painted panels containing 2,3 or 4 thermal elements depending on the model, are available in two different versions: with lowconsumption modulating circulators (P type) or with 2-way valves (type V).

The power supplied by the individual modules is managed with the new electronics control, compatible with the MOD-BUS protocol, which, thanks to advanced operating logics, ensures optimal management, as well as allowing the distribution of heat in a precise manner to the various circuits.

All the models are internally equipped with hydraulic manifolds, gas, condensation discharge and fume exhaust manifolds, thus making possible the internal installation with an open chamber and, with appropriate kits, the sealed or external installation, all in an extremely reduced space, ideal both for the new thermal power stations and for the old large systems.

Compactness, versatility and electronic management, coupled to the new patented double-acting stainless steel heat exchanger double-acting and the premixed burner with wide modulation range, make STEEL PRO POWER an extremely efficient and low pollutant system.

To help the designer in identifying the best solution, Riello has developed a configuration software to support the selection process of the specific accessory developed for this system.

CONFIGURATION

STAND ALONE

- Possibility of exhaust fumes / air and hydronic connections on the right or on the left

- Simplified maintenance operations thanks to the rotatable control display

- Simplified installation thanks to the terminal block dedicated to the wiring

- Indoor or outdoor installation (with accessory kit)

- Open or sealed chamber combustion (with accessory kit)

CASCADE

- Possibility to couple up to 10 modules

- Modulation ratio up to 1:50

- Side-to-side installation

STEEL PRO POWER is available in the following versions and heat inputs:

COMBUSTION UNIT

Each module of STEEL PRO POWER It is composed of a premixed burner functioning in synergy with the new heat exchanger, so as to obtain an efficient transformation of the chemical energy of the fuel into thermal energy available to water and contained polluting emissions, ensuring operation even in the most demanding conditions.

The heat exchanger, low in water, has been developed with the aim to quickly reduce the temperature of the fumes, limiting the pressure loss and ensuring an efficient heat transfer to water thanks to the high exchange surface

It is composed of two concentric spiral coils made of stainless steel, the inner one made with a smooth tube with a pentagonal section, while the outer one has a circular section, allowing the parallel movement of water with elevated DT in order to reduce the system start-up times.

On the hydraulic supply pipe of each module is installed a flow meter safety device able to control the water flow inside the exchanger, so as to ensure optimal working in all operating conditions.

The premixed burner has been designed to contain polluting emissions below the most restrictive European limits, allowing STEEL PRO POWER to be in Class 6 NOx according to UNI EN 15502-1.

In particular, it is equipped with a new modulating combustion group able to supply the power according to the needs of the system, ensuring for each module a 1: 5 modulation ratio, minimizing ON-OFF cycles, making STEEL PRO POWER suitable to be installed either as a replacement on existing systems or as a new generator on new plants for buildings with low energy content.

MODULARITY

Modularity is synonymous of flexibility and continuity of service, which must be associated with careful system management. For this, STEEL PRO POWER was designed by sophisticated electronic logics, in order to guarantee an efficient management of the single modules, as well as a careful coordination of their cascade operation.

To guarantee the correct hydraulic management, each module is equipped with non-return valves, which prevent the inverse circulation of water in the modules turned off, a condition that could be generated at partial loads.

ELECTRONIC CONTROL AND DISPLAY

Electronic STEEL PRO POWER regulation has complex tasks, having to monitor and process a lot of information coming from the plant quickly, in order to guarantee the best comfort to the user with the lowest energy consumption and maximum operational safety. The STEEL PRO POWER control it has been developed with great attention to the refinement of the calculation programs, the efficiency of the detection and the processing speed.

The operating logic of the boiler in "managing" and "depending" methods are preset and integrated into the electronic boards ensuring efficient cascade operation. The display interface is backlit, intuitive and multilingual, to simplify the dialogue between the machine and the operators.

STEEL PRO POWER uses a new generation control system that integrates the climatic regulation with advanced functions for the management of the plant.

Functions integrated in the control:

- Linear or curved climatic adjustment, in combination with the external probe

- Management of the cascade of the modules inside the cabinet

- Management of boiler cascades with Managing-Due logic

- Power control for operation a DT constant

- ACS production management and direct circuit

- Possibility of system expansion through accessory control additional heating zones (direct / mixed)

- Pumps modulating control (PWM / 0-10 V)

- Remote management via MODBUS

- External power control via 0-10 V input

- Automatic SUMMER / WINTER switching

The electronic regulation is completed by the new backlit display, easy to use, thanks to the intuitive menu that combines graphic elements with text strings. Allows the regulation of the system, including the distribution of heat on the secondary circuit, with climatic curves and time slots dedicated to each managed system; the user interface is equipped with 8 keys for menu navigation and for setting the operating parameters.

DISPLAY FEATURES

- Multilingual menu, multi-level tree

- Management of user profiles protected by a password

- Large backlit screen, 255x80 pixels

- Management of weekly time schedules

- Boiler error history

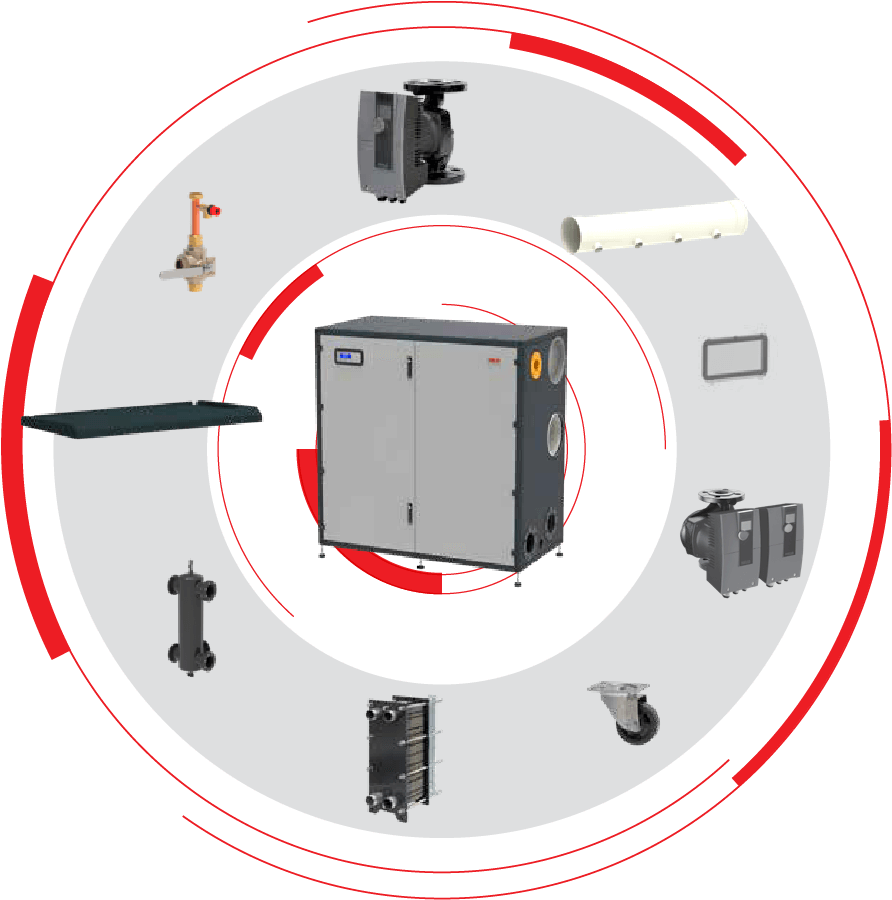

ACCESSORIES

STEEL PRO POWER is completed with a wide range of accessories able to adapt to the needs for each type of system. The accessories have been specially designed to maximize the flexibility of the system and to obtain the ideal solution for every installation requirement. All the models in the range, in standard configuration for indoor installations and open rooms, with the choice of suitable accessory kits that are easy to install, can be transformed into both a sealed configuration and an outdoor configuration.

Thanks to the specially developed accessory kits, it is also possible to connect the flue, air (if present) and hydraulic manifolds on both sides of the cabinet. For all models, the INAIL safety kit is also available, which is completed with specific fuel interception valves (VIC) and safety valves, both to be selected according to the model.

It is also possible to install a hydraulic separator or, to protect the boiler in case of installation on old systems, HEATGATE plate heat exchangers, for which combinations are available depending on the operating conditions on the primary and secondary circuits.

Both components can also be installed in specific technical cabinets.

For models "V", the circulation on the primary must be guaranteed by means of a suitable accessory circulators, selectable according to the heat input of the system, available in single or twin pump versions.

There are also a series of accessory kits useful for maintenance and service functions, such as interior led lights in the cabinet, displacement wheels, crane lifting support kit in addition to the PC interface kit.

16/10/2020