NEWS

CONDEXA PRO

ONE PRODUCT, A THOUSAND SOLUTIONS

Fully designed, developed and industrialized by Riello, CONDEXA PRO is the ideal choice for central heating systems of large domestic properties and commercial buildings, like hotels, sports centres, schools, office buildings, factories, etc.

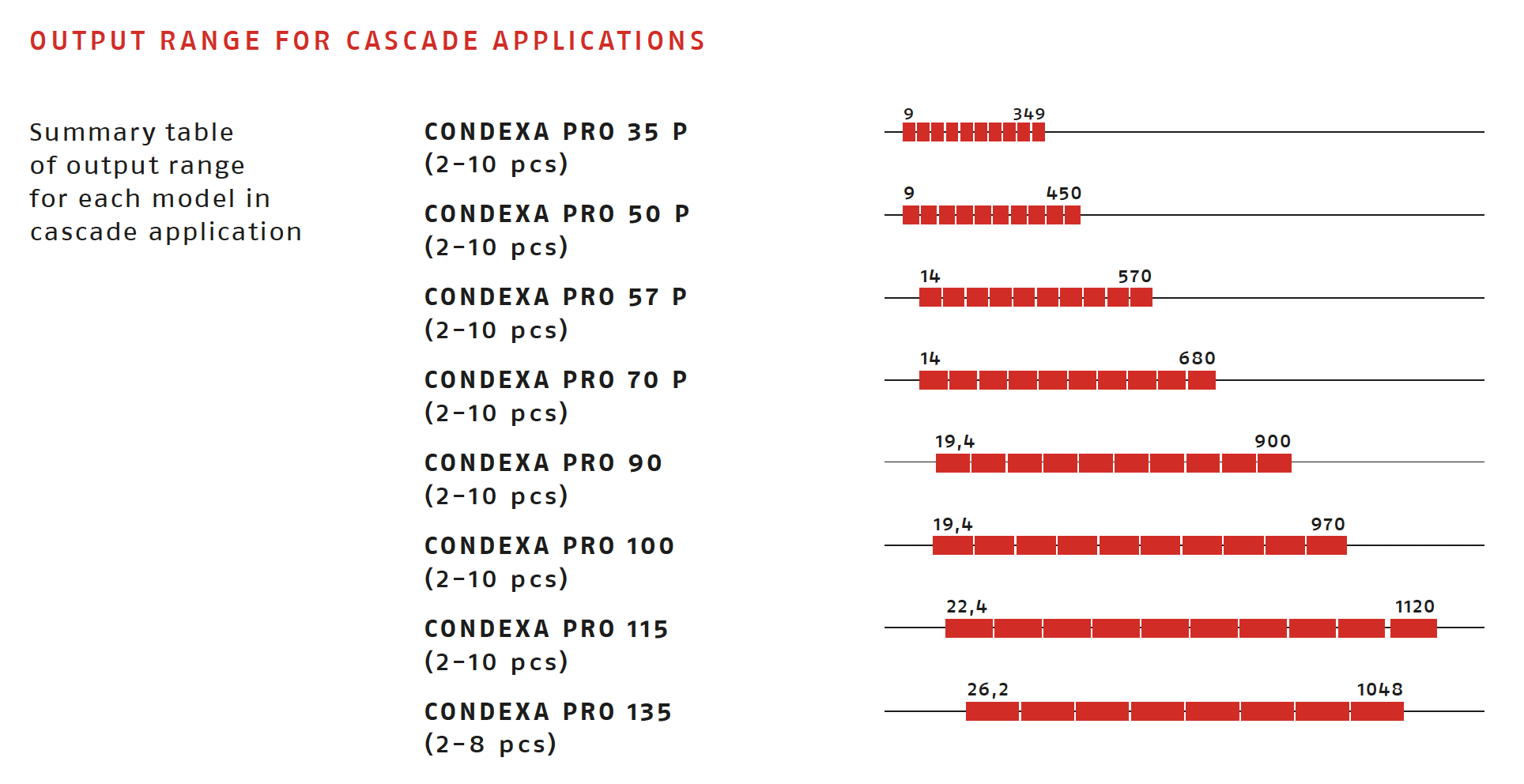

Thanks to an almost infinite number of possible configurations, ranging from a simple stand-alone to cascade applications of up to 1120 kW, CONDEXA PRO is Riello’s winning solution both for new buildings and renovations, from energy retrofitting to the replacement of old boiler systems.

The strength of Condexa Pro is the extreme flexibility of the system: thanks to the wide range of accessories, the basic unit transforms from a single boiler to a cascade module, from an indoor generator to an outdoor one, from a conventional flue to a room-sealed solution, and so on, to allow about 1000 possible installations that ensure the specifier and the Installer solve any situation and installation complexity.

The ease of mounting and the maximum flexibility of installation, combined with high efficiency and low emissions, make this product stand out in the category of commercial and light commercial appliances.

CONDEXA PRO, A REAL INNOVATION

CONDEXA PRO IS AN INNOVATIVE PRODUCT WITHIN RIELLO CONDENSING MODULAR SYSTEMS

All the components of the previous range have been redesigned: the heat exchanger works with surface temperatures decreased by 18% to reduce thermal shock and increase the lifespan; polluting emissions have been reduced below the most stringent limits (Class 6 NOx according to UNI EN 15502); the system control is 10 times faster than the previous one.

A new, wider range of accessories is also available as standard.

- NEW PATENTED CONDENSING HEAT EXCHANGERS MADE OF STAINLESS STEEL

- 8 VERSIONS FROM 34.9 TO 131 KW, THAT CAN BE INSTALLED IN STAND-ALONE OR CASCADE CONFIFURATION.

- POSSIBLE CASCADE CONFIGURATIONS UP TO 1120 KW WITH EMBEDDED ‘MANAGING/DEPENDING’ CONTROL LOGICS.

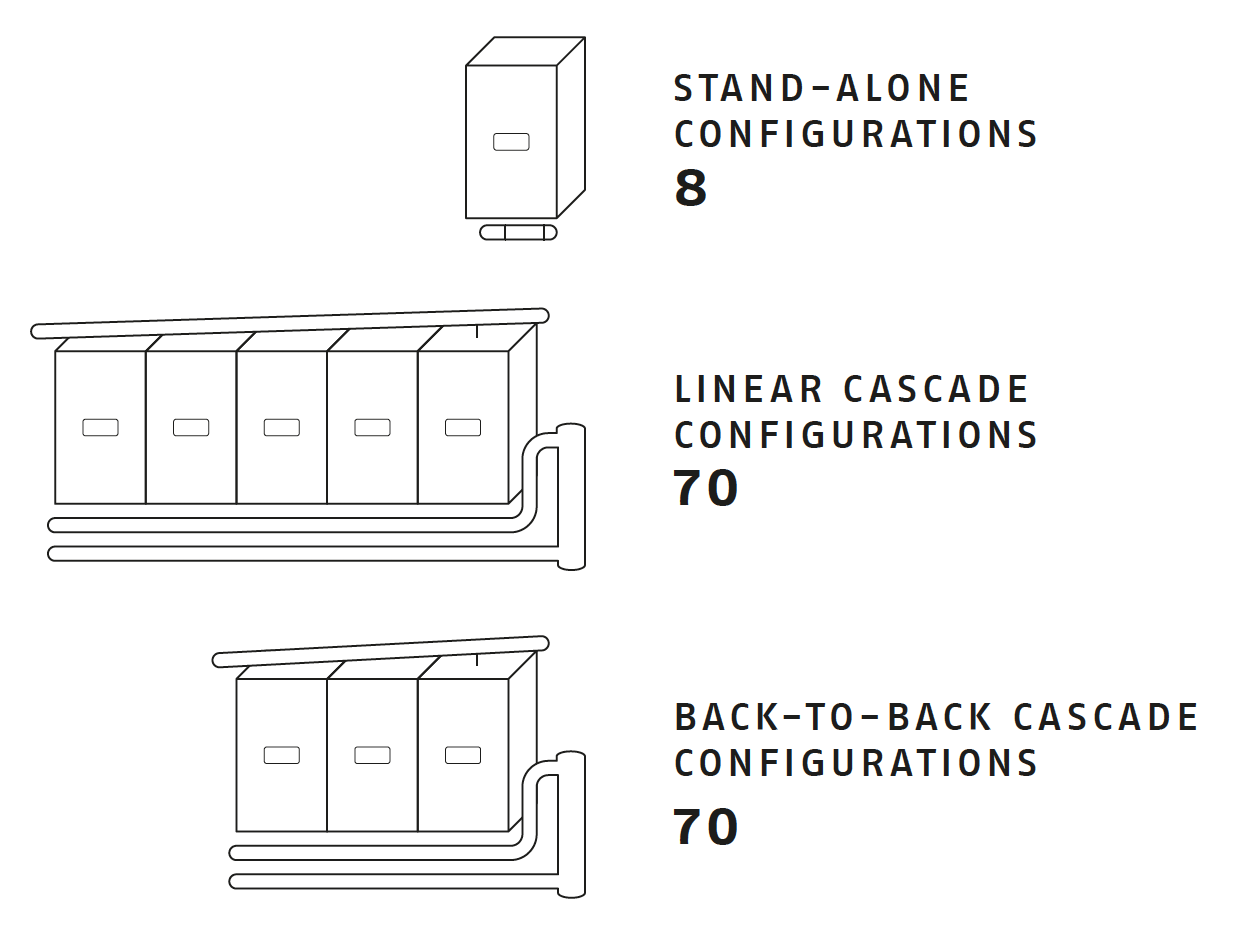

- POSSIBLE CASCADE CONFIGURATIONS WITH FRAME: LINEAR OR BACK-TO-BACK

- MODULATING AND MODULAR POWER REGULATION WITH AUTOMATIC BURNER IGNITION SEQUENCE REVERSAL.

- SIMULTANEOUS MANAGEMENT OF TWO DIFFERENT CIRCUITS: DHW TANK AND HIGH TEMPERATURE.

- UP TO 16 ADDITIONAL MIXED ZONES AVAILABLE AS ACCESSORY.

- AUTOMATIC SUMMER/WINTER REVERSAL.

- ‘ANTI-LEGIONELLA’ FUNCTION AS STANDARD.

- SUITABLE FOR REMOTE CONTROL MANAGEMENT (0-10 V INPUT OR MODBUS) VIA OPTIONAL KIT.

- AVAILABILITY OF A WIDE RANGE OF SYSTEM ACCESSORIES.

- LPG CONVERSION KIT SUPPLIED AS STANDARD.

- AS STAND-ALONE APPLICATION, CONDEXA PRO IS SUITABLE FOR OUTDOOR INSTALLATION, IN A PARTIALLY PROTECTED SPACE, BY MEANS OF AN ACCESSORY KIT, THAT RAISES THE ELECTRICAL PROTECTION TO IPX5D.

MAXIMUM APPLICATION FLEXIBILITY

Each model of CONDEXA PRO can be installed in cascade with up to 10 modules, except for CONDEXA PRO 135 tha can be configured with up to 8 modules. Considering the number of linear and back to back configurations, CONDEXA PRO range allows implementing 140 types of cascade configurations, which added to the single applications of the various models reaches 148 applications.

The number increases significantly if we add plate heat exchangers and hydraulic separators as accessory kits to these configuraions.

This adaptability allows CONDEXA PRO to stand out in the reference scenario of high power boilers, a plus that is increasingly appreciated also in the plant room.

USER INTERFACE

CONDEXA PRO electronic control has complex functions. It must monitor and quicly process several information, originating from the generators and from the installation, to produce the maximum comfort for the user with the minimum energy waste and the maximum operation safety.

The CONDEXA PRO control features fine calculation programs, an efficient survey and high elaboration speed.

The operation logic of the boiler in “managing” or “depending” mode, in case of cascade application, are integrated in the board and ensure the maximum application Flexibility.

The interface display is backlit, intuitive and multi-language, to simplify the dialogue between the unit and the users.

TEN GOOD REASONS TO CHOOSE CONDEXA PRO CASCADE SYSTEMS

1

MAXIMUM PERFORMANCE IN ANY CONDITION

The modulation of a CONDEXA PRO cascade system is considerably higher than that of a single boiler. In fact, through the control of the number of heat modules in operation, the system optimises the power delivered according to the actual requirements.

In the middle seasons - spring and autumn - when the demand is lower because of the favourable climatic conditions, or in buildings with very variable needs depending on the presences (Hotels and Restaurants), the cascade control will activate only the boilers required, ensuring the necessary power to meet the actual heat needs.

2

CONTINUITY OF SERVICE WITHOUT CONCERN

CONDEXA PRO cascade systems are much more reliable than monobloc boilers. In case of a unit downtime, the rest of the system is not involved and continues to operate to meet the heat requirements.

3

BEST CHOICE FOR REPLACEMENT

The modularity of CONDEXA PRO systems is the right solution in case of replacement of central heating system with difficult access to the plant room: each unit of the cascade can be easily transported and has reduced dimensions and weight.

4

MAXIMUM COST-EFFECTIVENESS FOR REPLACEMENT

The high efficency of the systwem, together with the condensing technology, make CONDEXA PRO system the ideal solution for energy retrofits.

There is no need to wait for the existing boiler to break down, as the cost of replacement pays for itself in a few years thanks to the saving on gas supply.

5

MAXIMUM RESPECT FOR THE ENVIRONMENT

Heat modules CONDEXA PRO have reached the best NOx emission class (Class 6 according to UNI EN 15502) thanks to the total premix burner with micro flame. Moreover, the cascade system manages the ignition of the burners, activating only those necessary for the current heat requirements, thus reducing CO2 emissions.

6

MAXIMUM EASE OF MAINTENANCE

The CONDEXA PRO range is designed for an easy maintenance with direct frontal access to all the internal components. Maintenance of the single module of the cascade system can be carried out even if the other modules are running.

7

MAXIMUM SPACE OPTIMISATION

The cascade CONDEXA PRO system is designed to take as little space as possible, so as to be suitable for both condominiums and commercial buildings. The compact size of the single module (1000x600x435 mm) and an innovative frame, able to contain more than 1 MW in 2.6 m2, allow installation even in small plant rooms.

8

MAXIMUM FLEXIBILITY

The CONDEXA PRO system is suitable for plant rooms where space is limited: thanks to the wide range of accessory kits, CONDEXA PRO is available for stand-alone wall-mounted application, or for cascade application, with linear or back to back configurations.It is also possible according to the requirements and the space available.

9

MAXIMUM EASE OF INSTALLATION

Cascade heat modules CONDEXA PRO can be easily installed thanks to the large number of accessory kits available. Every single module can be transported separately to the plant room, easily passing through any door. The installer will only have to assemble modules and kits with simple, easy and fast operations.

10

MAXIMUM MODULATION RANGE AND ELECTRONIC MANAGEMENT SPEED

CONDEXA PRO boilers feature an electronic board able to manage complex systems thanks to the precision of calculation programs and to the processing speed. Thanks to the onboard electronics, with the addition of the accessory kit for flue and hydraulics, it is possible to manage up to 10 modules in cascade, thus reaching a very high modulation ratio.

27/07/2020